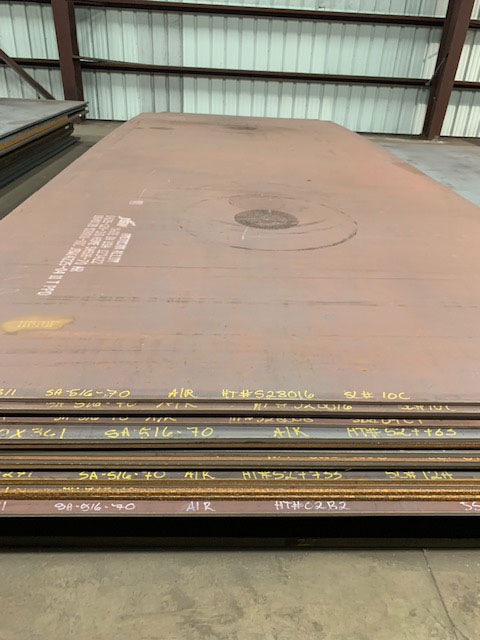

Overview of SA 516 60, SA 516 65 & SA 516 70

ASTM SA 516 Gr 70 is produced to a fine grain practice and is considered the backbone of the pressure vessel industry. Depending on the tensile requirements within the environment for both temperature and pressure, SA 516 Gr 60 along with SA 516 Gr 70 are more commonly used in refineries, chemical plants, power plant, and other moderate to low temperature applications. SA 516 is normally produced in the As Rolled condition for thickness’ 1-1/2″ and under. Normalizing is required for thickness’ over 1-1/2″

- Designed for moderate to low temperature environments

- Thickness’ up 1-1/2″ thick is traditionally supplied in the As Rolled Condition

- Thickness above 1-1/2″ thick is supplied in the Normalized condition. In addition we also stock Normalized material in thickness’ under 1-1/2″ as well.

- Stock thickness’ from 3/16″ – 12″ and widths up to 144″

Chemical Requirements

*Elements represented in percentage

| Elements | SA 516 Gr 60 (Grade 415) |

SA 516 Gr 65 (Grade 450) |

SA 516 Gr 70 (Grade 485) |

|---|---|---|---|

| Carbon, max Composition % | |||

| 1/2 in. (12.5 mm) and under | 0.21 | 0.24 | 0.27 |

| Over 1/2 to 2 in. (12.5 to 50 mm), incl | 0.23 | 0.26 | 0.28 |

| Over 2 to 4 in. (50 to 100 mm), incl | 0.25 | 0.28 | 0.30 |

| Over 4 to 8 in. (100 to 200 mm), incl | 0.27 | 0.29 | 0.31 |

| Over 8 in. (200 mm) | 0.27 | 0.29 | 0.31 |

| Manganese, max | |||

| 1/2 (12.5) and under: | |||

| Heat analysis | 0.60-0.90 | 0.85-1.20 | 0.85-1.20 |

| Product analysis | 0.55-0.98 | 0.79-1.30 | 0.79-1.30 |

| Over 1/2 in (12.5) | |||

| Heat analysis | 0.85-1.20 | 0.85-1.20 | 0.85-1.20 |

| Product analysis | 0.79-1.30 | 0.79-1.30 | 0.79-1.30 |

| Phosphorus, max | 0.025 | 0.025 | 0.025 |

| Sulfur, max | 0.025 | 0.025 | 0.025 |

| Silicon | |||

| Heat analysis | 0.15-0.40 | 0.15-0.40 | 0.15-0.40 |

| Product analysis | 0.13-0.45 | 0.13-0.45 | 0.13-0.45 |

Tensile Requirements

| SA 516 Gr 60 (Grade 415) |

SA 516 Gr 65 (Grade 450) |

SA 516 Gr 70 (Grade 485) |

|

|---|---|---|---|

| Tensile strength, ksi (MPa) | 60-80(415-550) | 65-85(450-585) | 70-90(485-620) |

| Yield strength, min.B ksi (MPa) | 32(220) | 35(240) | 38(260) |

| Elongation in 8 in. (200 mm), min, % | 21 | 19 | 17 |

| Elongation in 2 in. (50 mm), min, % | 25 | 23 | 21 |